In the winter of 2021, I received an internship position in a company named KGM (it is now changed its name to APEK hose) which produced rubber hoses and needed a polymer engineer to start the R&D department. Simulating rubber hoses before production was the vast majority task in this position. The idea was to study hose structure, model them into ABAQUS and then simulate standard tests such as Pressure tests, Bending tests, and Vacuum tests. As a polymer engineer, I was familiar with COMSOL but the simulations needed to be done in ABAQUS, and learning ABAQUS which was a great experience for me, especially with the help of Dr. Mirshahvalad.

Mechanical Simulations

- Mechanical tests are usually:

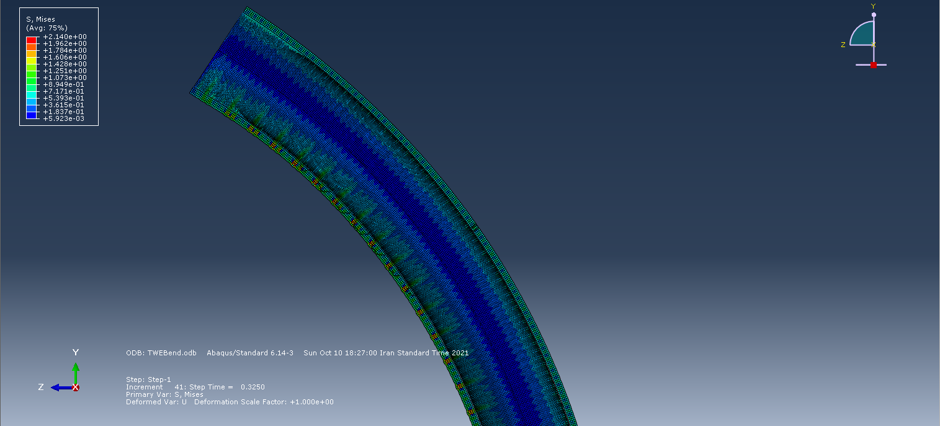

- Brust pressure test

- Bending

- Vacuum

- Adhesion test

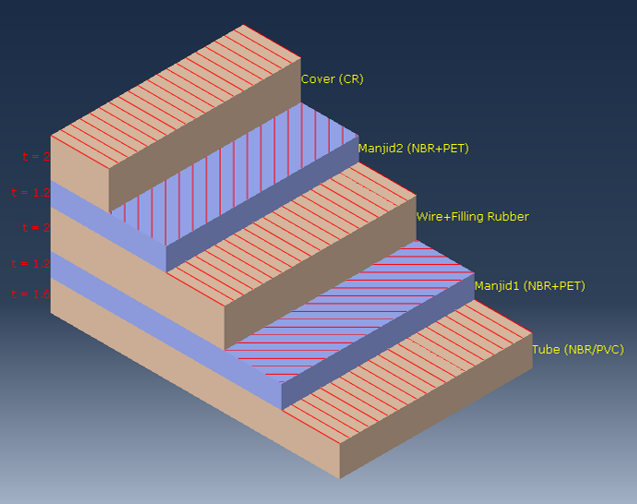

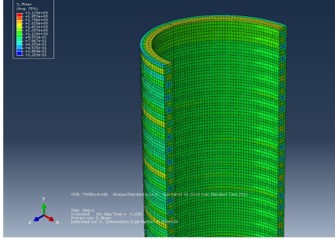

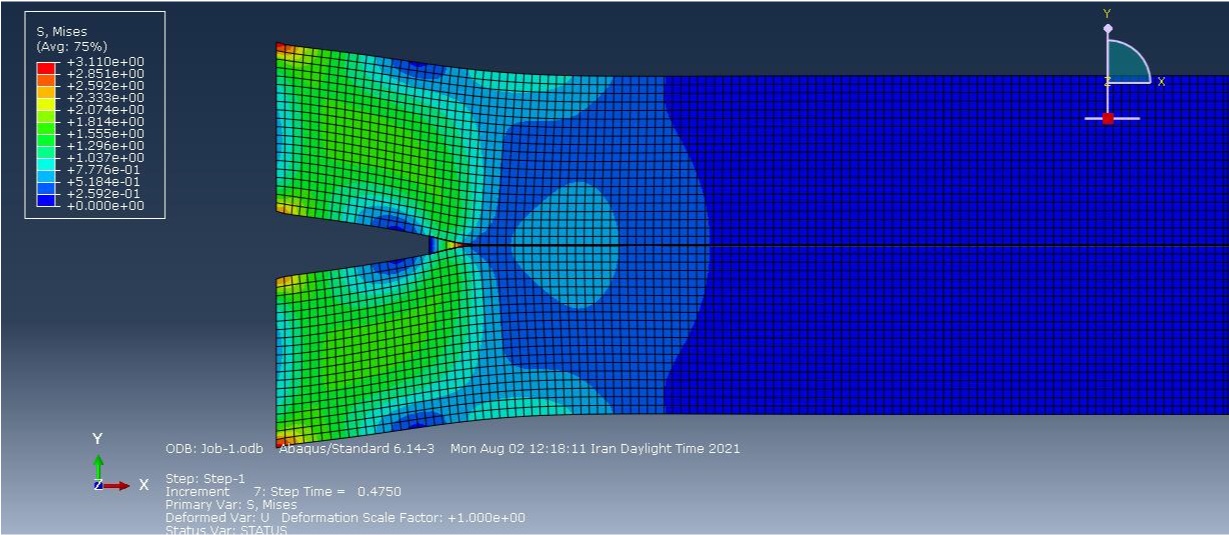

Firstly, the structure was studied and modeled into the software. After that, the mechanical properties of the material in the company were tested with the tensile machine. After setting materials parameters in the simulator, the different tests were run and the result was compared with realistic results. Because of many factors, there is a difference between simulation and experimental results, although there was the same trend between them.

Molecular Simulation

Rubber compounding is an experimental work and there is no specific formula to select materials for specific properties. I am passionate about controlling factors to reduce trial and error and this is one of the reasons that I like simulation. The curing process of rubber is a complex reaction and I hope I could do it in a molecular simulator such as Material Studio. Meanwhile, there are some specific forcefields (Such as ReaxFF) that can simulate reactions. Unfortunately, I cannot work with this force field in Material Studio and it needs coding which I don’t have time to learn.

The solubility parameter is my favorite property in polymers. Some hoses are Fuel hoses and they should not swell more than a specific value in contact with fuel. I use Material Studio to compute different combinations of NBR and PVC to find the best rubber for our work; however, I just study the rubber and no other ingredients and the result was close to real experiments.

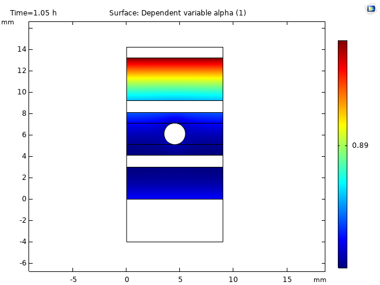

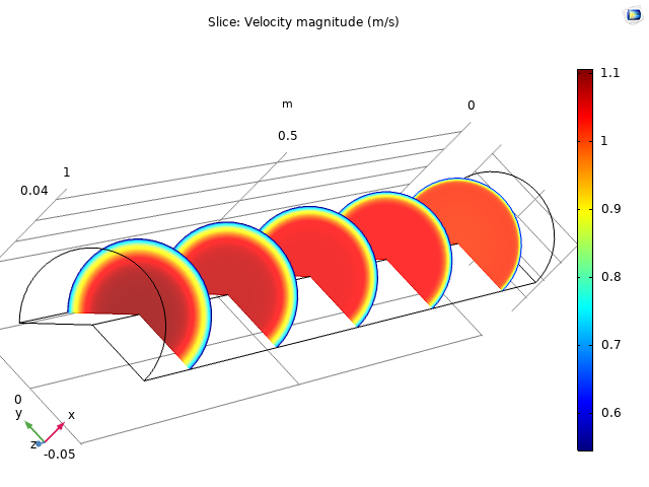

Curing Simulation

I am not the kind of person who sits down and just work with the computer in the office. I talk with the manager and I transferred to the industrial town to start the rubber laboratory. I learn to work with the tensile machine, durometer, rubber extrusion, rubber tablet and sheet molding, and a little about compounding. I read some articles about the simulation of rubber curing so I started this simulation with the rheometer which was available in the laboratory. I cure different samples at different temperatures and use curves to find the curing index and fitting kinetic models to them. After fitting I draw a part of the hose in COMSOL and specified the properties. Using the temperature trend in our autoclave, I run the simulation and it is really close to the experimental results.

To Put It in a Nutshell

Working as a polymer technician in this company help me to find my ability and weakness. I learned everything is not work and study. Also, if you do not enjoy your job, you cannot be successful it that. The most important duty for everybody is become aware about themselves and enjoy the life! Besides technical skills, I learn some soft skills such as presentation, negotiation, advertisement, and connection with other companies.